WB Industries embraces this lean manufacturing role to boost productivity and morale

THE FABRICATOR JANUARY 2019

JANUARY 16, 2019

BY MARK SHAIN

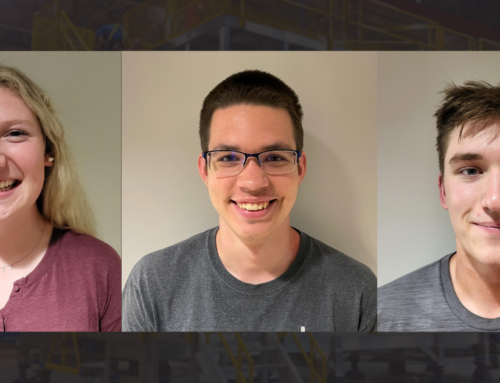

Before WB Industries appointed a water spider, all assembly hardware for one job was placed on a pallet and delivered to the area where employees were working (left). There was no easy way to verify quantities, and workers wasted a lot of time digging through the pile trying to find what they needed. Now all the hardware is well-organized in clearly marked bins that are in a logical order (right). Also, quantities are more easily identifiable. Another advantage is that the whole thing is on wheels, which allows the hardware to be brought to the job, eliminating steps and the need to find a forklift every time the hardware needs to be moved to a new location.

Under the lean manufacturing umbrella are many worker positions, some of which are more crucial to certain industries than others. In the heavy-duty fabricating and structural steel industry, a critical position that fits into the lean effort is the “water spider.”

Custom metal fabricator WB Industries, O’Fallon, Mo., created the position of the water spider for the sole purpose of improving productivity and morale. The job title is derived from the actions of the creature after which it’s named. In nature, a water spider darts across the top of the water in all directions, quickly and efficiently. It’s never in one place for too long, and it is always looking for that next location to speed off to.

These are the same characteristics of the water spider under the lean manufacturing principles of a heavy-duty metal fabrication operation. The purpose of the water spider is to perform quick, necessary tasks so plant workers on the floor do not need to stop what they’re doing. Perhaps they need a specific piece of hardware or tool, or maybe they are working with a gas tank that’s getting low and they need a new canister. The water spider can be alerted to the situation and quickly bring the new canister to the welder.

In the heavy-duty metal fabrication industry, keeping the welders welding is one of the top productivity requirements to meet key order deadlines. Often welders will need something from the toolroom during the day: a cylinder of gas, a spool of wire. The welders can flip a switch, triggering a light and alerting the water spider that they are in need of something to continue doing their work. It is the job of the water spider to immediately react to the signal and keep the production moving without interruption.

For fabricators that employ one person to handle the needs of the larger group, not only is the cost of the water spider’s salary offset by the increased productivity, but the floor workers feel supported and are generally happier in their work. At WB industries, one water spider supports more than 20 production personnel.

Misconceptions

The idea of the water spider has been around for some years now, but there are some common misconceptions about the role of the position. Some believe that the water spider is nothing more than a glorified “fetch person.” Some tend to think of this person as just somebody who is positioned to grab one tool or piece of equipment and carry it from one end of the floor to the other. If this were the case, it would certainly be more of an entry-level position. In fact, the water spider position is one of the higher-ranking roles on the floor. A good candidate for a water spider is someone who has multiple disciplines and has been in a supervisory role in the past.

In many industries, and heavy-duty metal fabrication included, a multitude of different operations are going on at the same time. This means that if one water spider is on the floor, this individual needs to have a deep knowledge of every operation that is taking place.

A Productivity Guru

Ideally, companies would like their water spider not only to keep everyone on the floor productive and happy in their work, but also to assess the floor as a whole. Therefore, the question of “How can we continue to improve our lean processes?” should constantly be running through the mind of the water spider while on the job. A water spider who is performing his or her job effectively should regularly be coming to management with ideas on how to make everyone’s job more efficient. Fortunately, these do not need to be very complicated ideas to be effective.

At WB Industries, the water spider recently handed management a list of items that needed to be addressed on the floor. Without having someone in this position, managers would not have known these issues existed. For example, workers were always searching for the extended forks for the forklifts. There was no assigned place for them, so the forks ended up in the last place they were used. To save searching time, the water spider recommended and built a rack for these pieces of equipment. The vertical rack uses minimal floor space and not only saves time, but reinforces to the workers on the floor that everything has its place.

Other Responsibilities

WB’s water spider also is in charge of the toolroom. He makes sure the consumable supply inventory is sufficient and orders new items as needed. He also ensures welders have everything they need to start working at the beginning of each day. At the end of their shift, the welders fill out a replenishment supply request that outlines what they’ll need the following morning to get to work as quickly as possible, as opposed to spending the first 30 minutes of their day collecting supplies. The water spider then fulfills those requests so that productivity is maintained.

The company’s assembly area houses tens of thousands of pieces of assembly hardware. In the past workers would be in the final stages of a job with a tight deadline, only to discover they were short a few specialty nuts or bolts. Now the water spider counts hardware before a job starts and organizes it on racks so workers can find what they need quickly and efficiently. This makes the assembly department incredibly efficient.

The Benefits

While adding the water spider position increases a company’s overhead, the savings in efficiency and productivity cannot be overstated. WB Industries introduced a water spider into its operations in July 2017, and since that time the company’s productivity has increased consistently by 17 to 21 percent over the same period last year.

Mark Shain is plant manager at WB Industries, 1270 W. Terra Lane, O’Fallon, MO 63366, 636-272-2366, www. w-bindustries.com. Photos courtesy of WB Industries.